Creating Standard Operating Procedures Around Pest Management for Food Processing Plants

“Old habits die hard” is a popular idiom one often uses to describe particularly annoying habits that never seem to go away despite best efforts: biting nails, smoking cigarettes, procrastination, etc. It’s understood that this behavior isn’t beneficial to one’s well-being and possibly detrimental, yet certain parts of the brain learn to accept these actions as part of one’s life, becoming rather difficult to change over time.

Pest management comes with its own set of “old habits” that are equally difficult to break, which could eventually cause a rampant infestation in your food plant. As a food processing plant manager, your margin for error with pests is miniscule. A presence inside your building can have drastic consequences, both to your operations as well as those you serve. In this blog installment, we share three key standard operating procedures for pest management in your food processing facility. Hopefully this will give you some tools to help instill new habits in your staff.

Shipment Inspection

Think for a second on the number of shipments you receive on a daily basis. Envision the number of boxes and pallets accepted through your doors, and the different transportation employees that visit your plant. An opportunity for a pest invasion exists each time the building’s loading bay doors open to accept a shipment, with cockroaches and rodents lurking in the crates and pallets.

Creating a written checklist for inspection can easily reform your shipment acceptance methods. The protocol should cover the following: an assigned employee to thoroughly inspect the vehicle delivering the materials as well as the actual boxes, a signed report detailing what was reviewed and any faults detected, and a final account of the shipment to save for your building’s recording process. Though challenging at first, this procedure will only improve with continual practice. Eventually, this crew should be able to complete the process in minutes.

As a final note, your facility needs to have a zero-tolerance policy with pests discovered in cargo. Employees that discover contaminated goods should reject the entire load.

Garbage Inspection

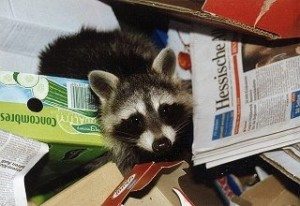

“Trash duty” is the least glamorous job and may feel somewhat demoralizing to those performing the task, but it’s possibly the most essential part of maintaining a pest-free environment around your facility. You may be discarding perishable items that can attract flying insects or expired grains that rodents can feed on, so you should manage your trash receptacles with the same scrutiny as your machine floor.

In addition to regularly scheduled dumpster pickups from a trusted waste management company, you will have to perform daily inspections of the garbage receptacles surrounding the exterior. Make sure that all waste is packaged appropriately and no spills are dripping along the sides of receptacles. Similarly, best practices indicate a scheduled cleaning of all garbage holding devices. This is more than just spraying soap and water along the insides, but a thorough cleansing by using high-quality chemical cleaning products.

A firm garbage policy must also be upheld on your building’s interior. Any machine spills or littered materials must be cleaned up in a timely matter. Minor accidents can turn into pest breeding grounds, so address a spilled soda can in a similar fashion.

Plumbing Maintenance

Open water sources sustain pest life. This may seem like an obvious statement, but it’s often the most overlooked element in a facility with regards to pest management. Rodents and insects will find any available water and begin inhabiting the area surrounding that puddle, however small or large it may be.

Thus, you should preemptively inspect any sources of moisture around your building and look for leaks. White residue coating a pipe’s surface is a good indicator that a leak may occur. Have each machine’s operator inspect for this, as well as any oil spills that may have occurred. Cooling units should also be included in this review, as condensation could build up and pool water around the machine.

Similarly, remain cautious when storing your mop after use. If not stored appropriately, the mop can also create a hospitable environment for pests. We recommend storing this at least six inches off the ground and placing the mop end in a fashion that doesn’t allow for dripping.

These are just a few tips on starting proactive pest control measures in your food plant. If you are an audited facility, make sure to review the guidelines because auditing agencies have their own control measures in place.

If you’re in need of a pest management program for your food plant, contact Holder’s for more information on our services.

Creating Standard Operating Procedures Around Pest Management for Food Processing Plants Serving

Houston

Beaumont | Conroe | Spring | Pasadena | The Woodlands | Richmond | Galveston

Baytown | Bryan | Cleveland | College Station | Cypress | Pearland | Sugar Land

Home » Creating Standard Operating Procedures Around Pest Management for Food Processing Plants